TRVVPS shielded twisted pair drag chain cable (800)

Characteristic

♦ Conductor: made by twisting multiple 0.08-0.12mm 4N grade oxygen free copper wires

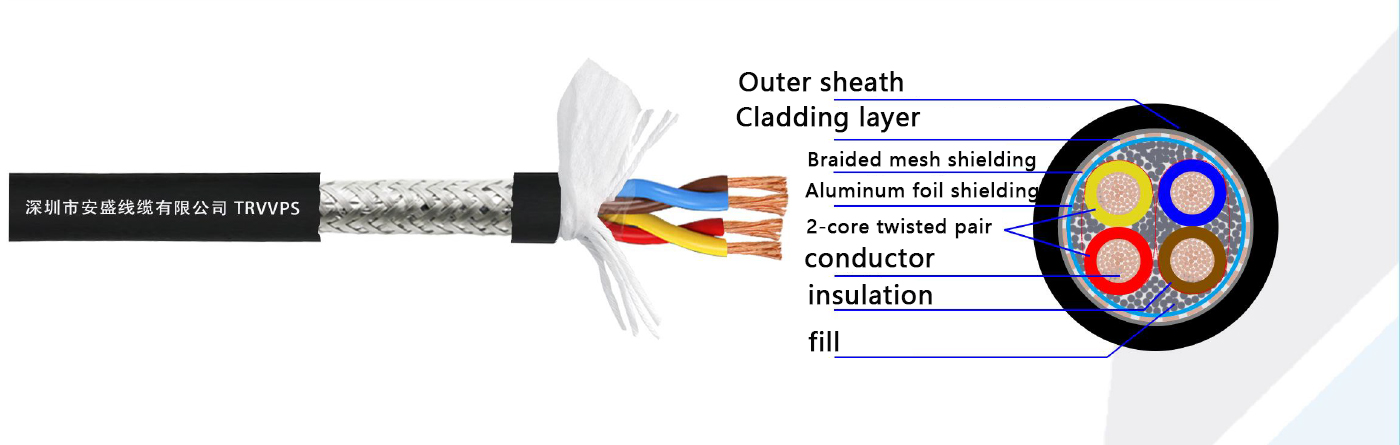

♦ Filling: cotton yarn

♦ Long term allowable working temperature: fixed installation (-30~+90 ° C); Mobile installation (-20~+90 ° C)

♦ Minimum bending radius: fixed installation, with a bending radius of 5XD; Mobile installation, with a bending radius of 7.5XD when the stroke is less than 10 meters; When traveling A10 meters, the bending radius is 10XD

♦ Product characteristics: Environmental protection, oil resistance, wear resistance, bending resistance, high flexibility, anti-interference, etc

♦ Insulation: Special mixed PVC material ♦ Wrapping layer: non-woven fabric

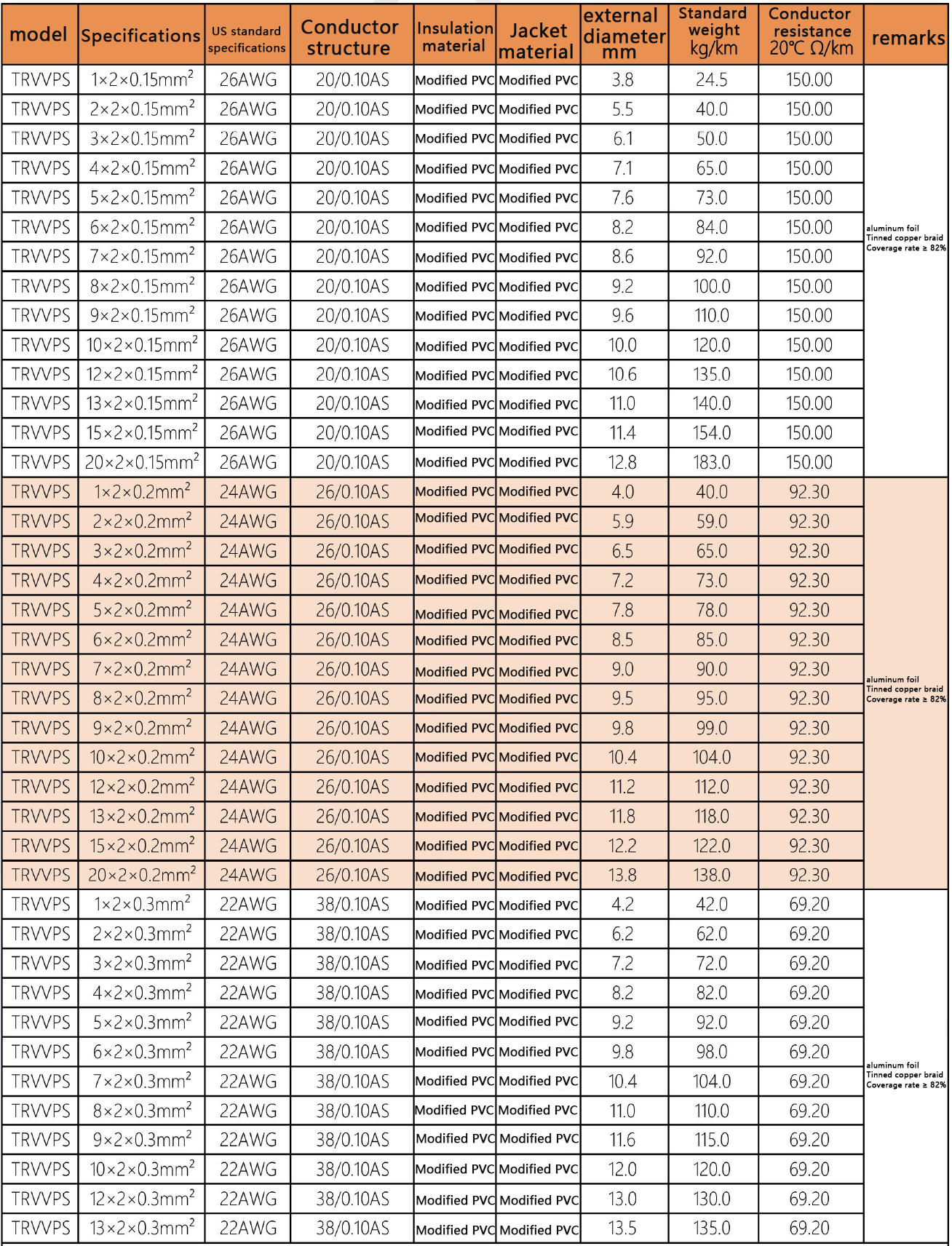

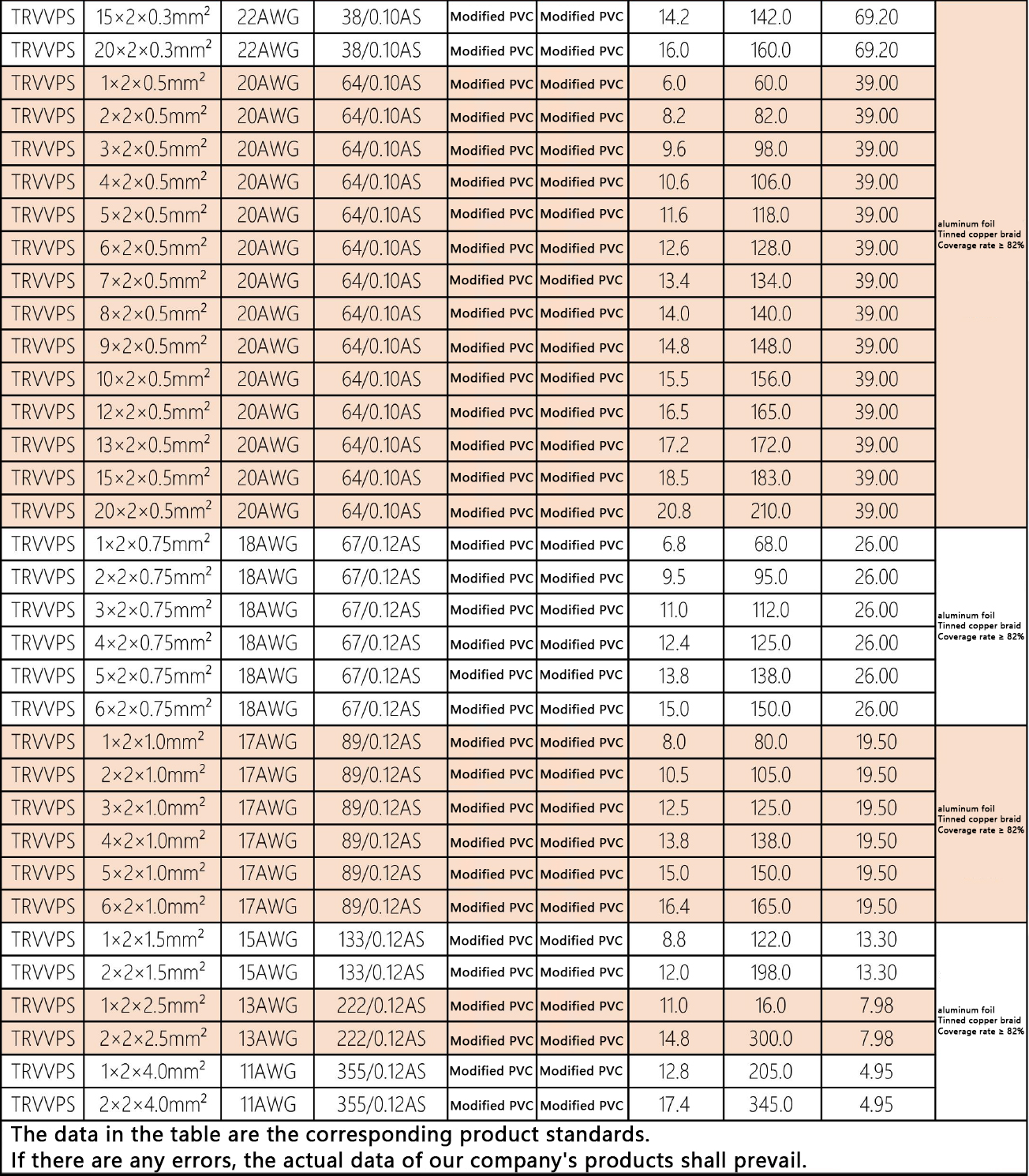

♦ Number of cores: 2-40 ♦ Shielding layer: aluminum foil+tinned copper braid

♦ Square number of conductors: 0.15-4mm2 ♦ Twisted pair: The core wire is 2-core twisted pair, and all wires are twisted into a cable

♦ Sheath: Special mixed PVC material ♦ Core wire color: color or monochrome coding

♦ Rated voltage 300/300V ♦ Conventional sheath color: black matte finish

Testing

Voltage test: 2KV/5min (10A) (AC)&1.5KV/5min or 2000V/5min (10A) (AC)

Bending and flexion test: Simulate the movement speed in the drag chain to test various conditions of bending and movement. Take samples from the finished product and fix them according to the standard method. The bending radius is r=7.5D, s=600mm, and the speed is 90 cycles/min; Movement speed: overhead speed of 3m/s, sliding speed of 2m/s, over 6 million times. Insulation and sheath performance testing: according to the corresponding standard performance of the material

Construction